Pressure Sensor Info

So you want to measure a pressure? Gauge or absolute? Air or liquid? If air, gauge, absolute, or differential? What range of pressure? How does it connect?

If we want to determine what pressure sensor is best, we need to understand the terms. The pressure that we read is really in relation to some other pressure. When it’s a gauge pressure, it’s like a tire gauge and measures versus the standard atmospheric pressure. If it’s absolute pressure, it measures compare to absolute vacuum. If it’s differential pressure, it measures against a point you get to pick! Gauge pressures are used for things like fuel, oil, coolant, power steering, and brakes to name a few. Absolute pressures are most often seen on intake manifolds and turbo applications. Differential pressures are used for measure the effectiveness of something and are seen on intake tracts, radiator shrouds, airspeed pitot tubes, aero pieces.

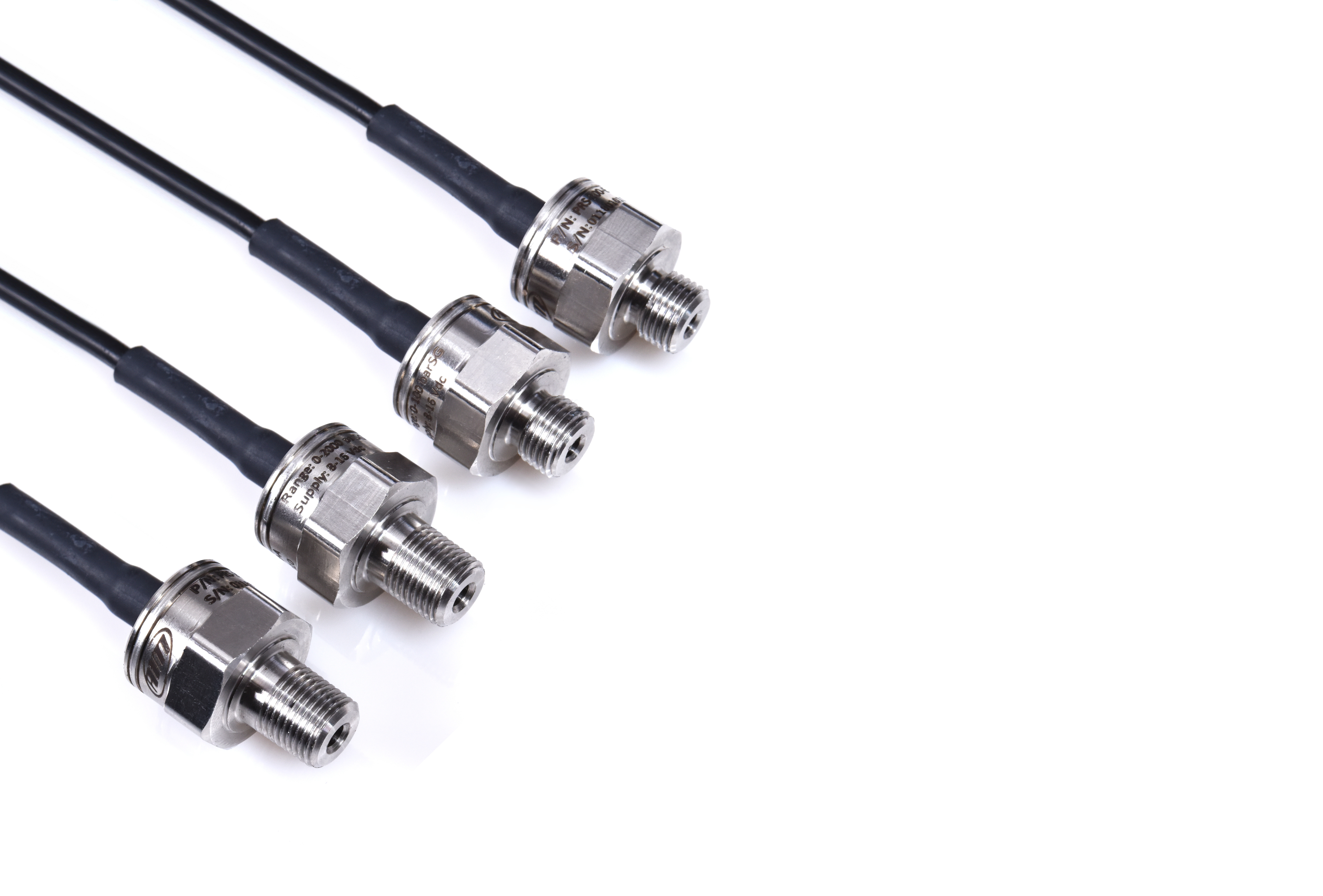

Liquid versus fluid is often easy to determine. At TrailBrake.com, the only thing that is usually effected by this is the differential pressure sensors that are for air only. One great thing about the AiM pressure sensors is that they are completely made from non reacting stainless steel, so they are good with fuels, coolants, oils, methanol, and more.

Then we have the connection method. In the AiM sensors come in a wide variety of threads. You can get 1/8” NPT, M10, and 3/8-24 male which is more commonly known as -3 AN. This allows you to match factory sensors or plumb into a system without having to use an adapter or worse, multiple adapters.

Finally we get to the range. The AiM pressure sensors come in a large range up to a low of 15 psi up to 160 bar (2,352 psi!). This allows you to pick a range that maximizes the resolution of the sensor and the system. With PSI options of 0-15, 50 psi, 50 psi absolute (-14.7 to 35.3 psi), 150 psi, 300 psi, and 3,000 psi, there are a lot of standard unit choices. In metric choices we have 5 bar, 0-5 bar absolute, 10 bar, 100 bar, and 160 bar versions. If you’re using an AiM system, you can use any sensor and choose to display the readings in your unit of choice with a few clicks of a button. If using none AiM systems, you get full calibration data and pinouts to make the configuration a breeze.

What if you want a temperature too? AiM makes a 0-50, 0-150, and 0-2,000 psi pressure sensors that also has a PT1000 temp sensor output. Now with one connection, you can get pressure and temperature information from the sensor. This makes the plumbing and wiring easier than ever!

For air pressures, TrailBrake.com has developed a number of differential pressure sensors. Most often seen packaged with our Pitot Tube Airspeed sensors, they are often used to investigate airbox efficiency, NACA duct pressure, and aero device testing. They are available in 2 kPa, 4 kPa, and 6 kPa ranges.

A specific pressure sensor is the TPMS sensor that measures the pressure inside your tire. They give great information about tire management and performance straight to your data system. Available in external or internal varieties, they are one of the best values in sensors in our opinion to learn how to tune your car.

Have questions about what the best sensor is for your application? Call or contact us and we will make sure you get the best sensor for your needs!

Recent Posts

-

Position Sensors

So you want to know where something is? There are a lot of options! In motorsports we measure the po …Feb 2nd 2025 -

Pressure Sensor Info

So you want to measure a pressure? Gauge or absolute? Air or liquid? If air, gauge, absolute, or dif …Jan 22nd 2025 -

Driver health, monitoring, and performance

I was surfing Instagram and saw Dr. David Ferguson, of the Spartan Motorsports Performance Lab, post …Mar 22nd 2022